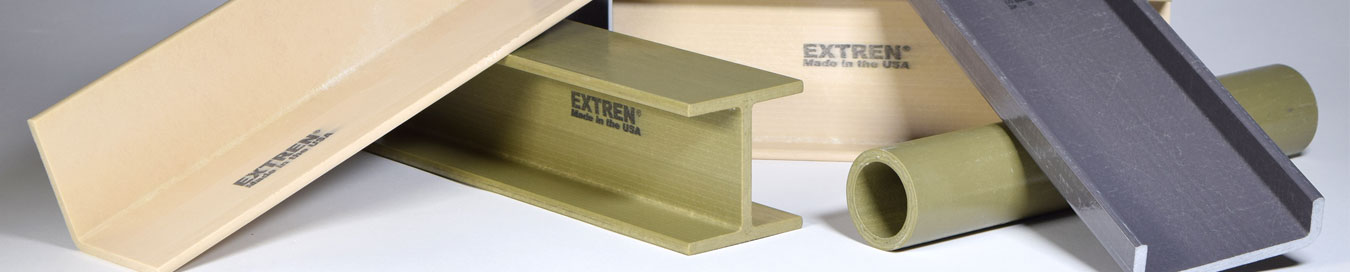

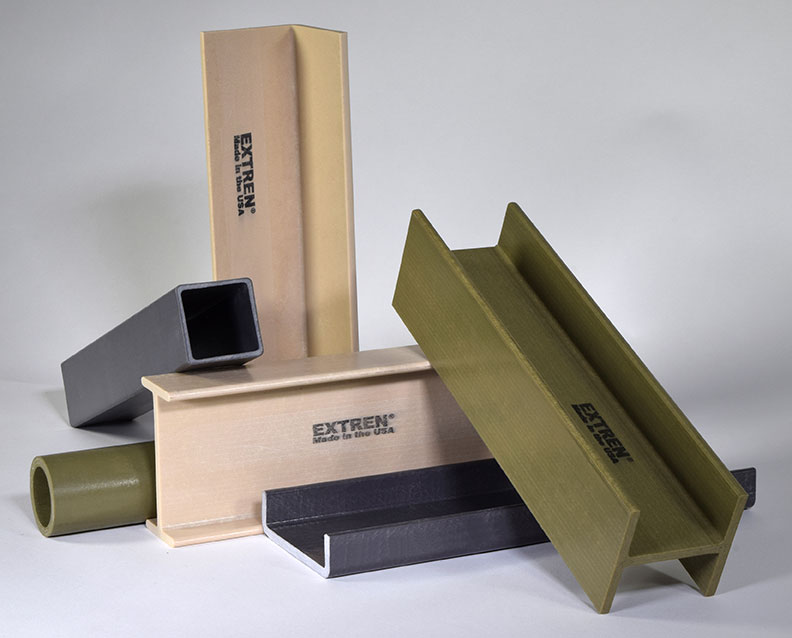

The construction world is governed by the International Building Code know as the IBC. This code is developed by architects and engineers across the globe to ensure stronger and safer construction methods. Typical construction projects use lumber, engineered wood, masonry, concrete, steel, and aluminum for structural applications. The 2006 IBC added a new category for Fiber Reinforced Plastic (FRP). This specification allows FRPs to be used as a structural component, and why we refer to the FRP product line as structural fiberglass.

Many industries inclusing automotive, aviation, and marine/boat markets have all used FRP products for decades. Hammers, shovels and other tools now utilize FRP and offer a stronger, longer-lasting handle.

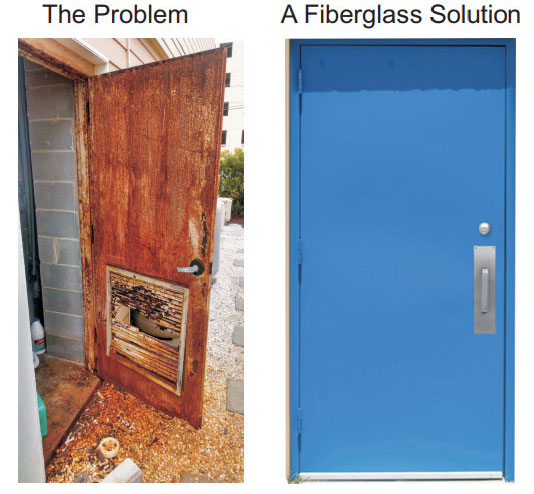

The typical reason for utilizing FRP in construction is to eliminate rusty metal and/or rotten wood. Best of all FRP is a double green product. It is not only less harmful for the environment than treated lumber or metals but it will always be the lowest life cycle cost of any structural material. Yes, it is Green for your wallet.

Maintenance expenses in concrete and steel buildings, we see replacement of rusted steel and corroded aluminum as the major costs. Especially when salt or salt water exposure is present, metal products deteriorate quickly.

Hollow metal doors, windows, metal stairs, etc. quickly rust and become a blemish on the exterior of the building. The repair and replacement of these items is very costly. And by replacing the doors, windows or stairs with new metal, all that has been accomplished is restarting the maintenance clock.

We know the rust will return and typically sooner, rather than later. New metal can be better protected by using premium paint or coatings technology. But this is typically not the choice, but rather a fast, improper paint job is completed and the corrosion clock begins to tick. Proper maintenance schedules for metal products may require annual or semi-annual painting to keep the corrosion at bay. Once the rust begins it is impossible to stop!

By utilizing structural FRP products, the annual paint maintenance is eliminated. FRP is a very stable substrate thus does not expand and contract like lumber, steel or aluminum. This low coefficient of expansion allows for dramatically less expansion and contraction, thus less stretch or compression of the paint coatings. This is one of the big cost savings on large airplanes. It costs millions to paint a Boeing 787 and a lot of down time. By utilizing Carbon Fiber (FRP), the aviation industry has dramatically reduced their paint schedule over the 56-60 life cycle of a plane. We feel that if you have a building with a 60 or more years of life left, you should manage any repairs to be made with that life expectancy.

We have The Last Resort, an ocean front hotel with a life expectancy of 40 years. The hotel has 300 hollow metal entrance doors and frames that need replacing. The cost for replacement doors staying with metal was $1900 per door or $570,000. This is for materials, new hardware, install labor and painting. The FRP quote was for $2600 per door totaling $780,000. That is an additional $200,000. So the question is what does the $200,000 buy and how will it pay off?

With metal doors they will need to be painted annually at $100 per door or a cost of $30.000 annually. The FRP doors will have a 15+ year paint cycle. Saving $30,000 per year. The break even is some where in year six. If the metal door has a 10 year life, the building owner will save $300,000 in painting over the 10 year period. That is a 50% return on the $200,000 spent over 10 years.

In year 11 the BIG Savings Hit! The metal doors are rusted and look poor thus needing replacement. Inflation has taken the door cost to over $3200 per door or $960,000 for the project. The hotel will loose 1/3 of it’s room rental for a period of 12 weeks. Just imagine what the door replacement will cost in year 30, 40, 50?

The hotel that installed the FRP doors just keeps on ticking. All the rooms are available for rental, so no loss in the revenue stream. The doors at year 11 look like they were recently installed. Management believes that they may need painting in year 20. Yes, the annual painting costs went to $0 for 2 decades. The original investment of $200,000 has saved the owner:

This is an very real life situation. The FRP doors have added value to the property by never rusting. Who likes to look at painted over rust? The doors will not dent so they look new for decades. The management decision to employ FRP will save over $8 million dollars on door replacements of this ocean front building over the next 60 years. That is a great investment for any building owner. This story ended different. The hotel owner sold the building after 15 years. So he saved:

The $200,000 investment payed out $1,150,000 over 15 years! Best of all the hotel sold at a 10 fold on net income. Thus the reduction of the $30,000 annual paint expense increased the bottom line by $30,000 per year. Thus the hotel sold for $300,000 more than had it had the expensive to maintain metal doors.

There are also many soft cost savings and or benefits like the time it takes to contract and manage these painting projects and replacements. We all recognize that these projects will cause down time and loss of room revenue. What is the value of Looking Good for decades with no or little maintenance?

FRP brings huge savings to the table for any project whether it be stairs, railings, doors, windows or what ever. With A Fiberglass Solution we can eliminate corrosion expenses!